Scientific analysis of the design, construction

and operation of synthetic pitches in Norway

Author: Bjørn Aas, COWI, Norway

published in sb magazine 2/2023

The subject of the KG2021 survey was the analysis of synthetic turf pitches with organic or non-infill systems over two to five years of operation, taking the example of six Norwegian pilot pitches. During the project period, the scientists worked on the life-cycle cost analysis, maintenance and users’ perceptions. They studied the value chain of the project from delivery and operation to removal and recycling of old carpets. Björn Aas – former Senior Engineer at SIAT (Centre for Sports Facilities and Technology) at the NTNU (Norwegian University of Science and Technology) and member of the IAKS Expert Circle for Outdoor Sports Surfaces – shares the latest findings and conclusions of the project

The main objectives of the project were the following:

- Reduce migration of microplastics from synthetic turf pitches by >80%

- Reduce the quantities of synthetic materials by >85%

- Reduce heavy metal pollution by >90%

- Obtain a recycling rate of >60%

- Extend the service life of synthetic turf pitches

Photo: Anna Heistad

Pitch construction

Photo: Lars Skjevdal, Endre Blikra

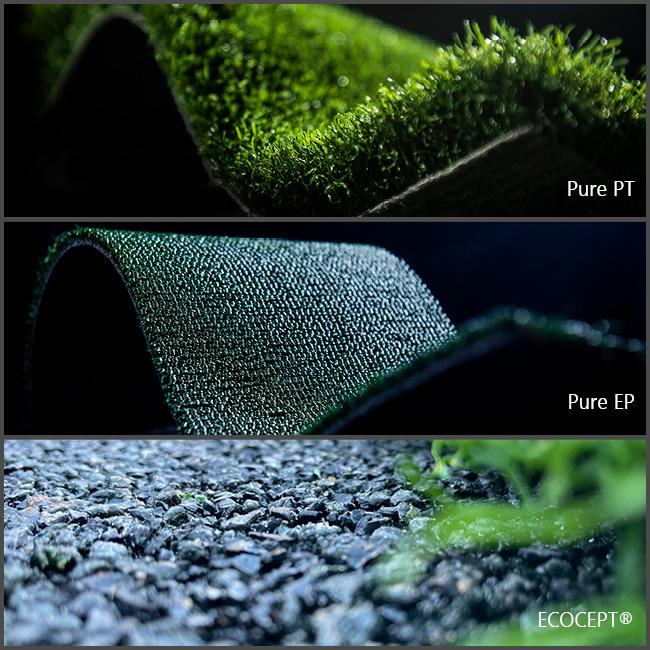

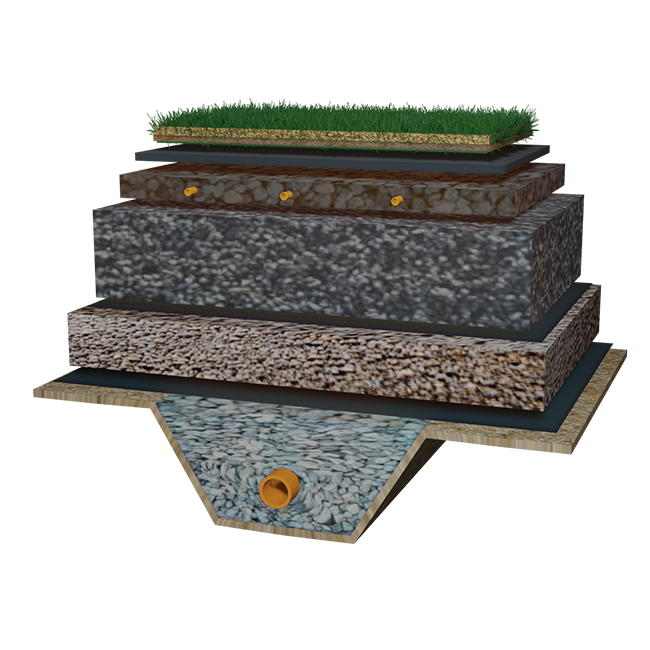

During the project, a special task was defined to determine a design guide for a complete pitch, from the drainage system to the carpet. The work was carried out in cooperation with an experienced contractor in Norway, and the results are available as construction drawings as well as bill of materials. The construction and design task were limited to systems without synthetic infill and that used an e-layer as shock pad. A special subtask involved the design of a rainwater retention system, and the use of a football pitch as a means of limiting the rainwater run-off from the surface. The two best-performing pitches in the pilot study have both implemented this design concept, and the importance of a proper base design has been proven during heavy rainfall at on several locations.