In the LANXESS arena in Cologne, Germany the ice hockey cracks of the Kölner Haie are guaranteed perfect ice. This guarantee is also grounded in technology from Italy: WM technics supplies WM Connect, a system that represents a “quantum leap” in efficiency and sustainability in ice resurfacing.

It is one of the largest multifunctional halls in Europe. Its schedule includes major concerts, significant sporting events, and hilarious carnival shows: the LANXESS arena in Cologne is an event hall par excellence. It is particularly well-known as the venue for the home games of the eight-time German ice hockey champions, the Kölner Haie. And for the best of the best, only one thing comes into question: the best of the best - in the case of the Haie, a perfectly prepared ice surface on which the Cologne team competes for the championship title every year.

WM technics: A revolution rarely comes alone

This season, the Haie do find themselves in the middle of the pack. But there is still a long way to go, and that should not defy the fact that only the best ice is good enough. To this end, the Mammoth ice-resurfacing machine from Italian manufacturer WM technics has been pulling its rounds with electrical quietness for the past six years.

An ice-resurfacing machine with an electric engine is undoubtedly one of the most revolutionary advances in the industry in recent years. But anyone who knows WM technics knows that the ladies and gentlemen from Prato all’Isarco in South Tyrol don’t like to stand still - and already have the next milestone in the starting blocks.

WM’s latest achievement is called WM Connect. It certainly doesn’t take an energy crisis like the current one to make us more emphatic about our energy consumption. However, it is precisely this crisis that has increased our focus on it. With WM Connect, WM technics provides its customers with a tool to meet these new demands in energy management.

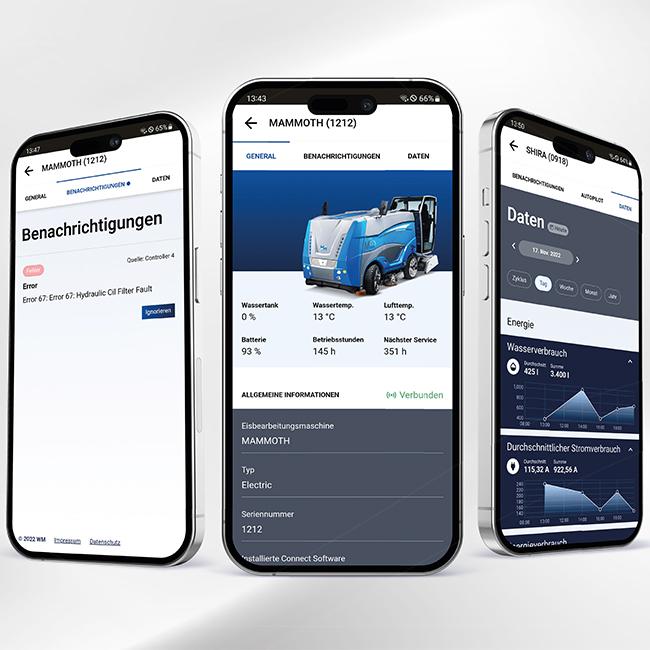

WM Connect: Real-time data, communication tool, and e-shop all in one

WM Connect is a data tool, communication assistant, and e-shop in one. A sophisticated system that kills three birds with one stone in terms of efficiency through real-time data collection, over-the-air error messages, and access to the WM e-shop “WORKspace”.

The centerpiece is the real-time data collection: the system collects data on water consumption (litres), electricity consumption (amps), and thermal energy required (kWh) during each ice processing operation and displays it live on the dashboard provided. The dashboard can be accessed anywhere: with a smartphone, a PC, a tablet, or the WM screen.

Fotos: WM GmbH

“We can now make resource consumption more sustainable”

Photos: WM GmbH

WM Connect is a game-changer for us, especially given the increased energy costs. With the available data and corresponding field tests, we can determine exactly how much energy and water we need to create the perfect ice without wasting resources,” emphasizes the CEO of the Arena Management Gmbh Stefan Löcher, “so we can already adjust and plan our budget accordingly. In addition, we have an ideal basis for year 2023 to make investments in the various resources in a more targeted manner and to operate more sustainably.”

“More targeted” and “more sustainable” are also the buzzwords for the following features of WM Connect. Let’s first turn our attention to over-the-air access: automatic error messages from WM Connect mean that ice makers are always up to date regarding errors in the system. As soon as such a message is displayed, they can immediately contact the WM technics technicians, who promptly recognize over-the-air which adjustments are required.

WORKspace offering fast service

Technicians and customers deal with the problem over the phone, and customers save themselves cost-intensive on-site repairs and avoid associated environmentally damaging transfers of technicians.

Suppose it turns out that a component of the ice machine needs to be replaced. In that case, access to the WORKspace allows fast action: Components are identified, searched for, found in WORKspace, ordered, and arrive at their destination within 24 hours.

If one of the machines named Shira, Mammoth, or evo² features an autopilot, this can also be controlled easily via WM Connect.

WM Connect stands for increased efficiency and full sustainability

For Mirko Sparber, Sales Manager of WM technics, the new tool is a quantum leap: “WM Connect is the control centre of our ice resurfacers. It raises user-friendliness to a new level and makes life much easier for our customers and us. More precise budget planning, imminent service, fast communication: we want our customers to work more efficiently and sustainably in all respects – and we have achieved this with WM Connect.”

In the LANXESS arena, WM Connect has been extensively tested and is now a permanent part of the repertoire. This is entirely in line with the management’s wishes in Cologne, to the delight of WM technics and especially to the benefit of the Kölner Haie cracks, who will find sustainable, perfectly prepared ice in their home arena for their title hunt.

Contact us